|

GMC Western States |

|

Tech

Center Number 29 - June 15, 2000 |

|

FROM UNDER THE SHADE TREE

IN UKIAH |

By Chuck Aulgur

We again had some great technical sessions in Ukiah. We learned

everything you need to know about toilets, holding tanks, and

waste technology from MicroPhor Company. Duane gave his usual

good session on "What Every New GMC Owner Should Know",

plus he had a lot of follow up discussion. The session on "Bring

Your Written Question To The Panel Of Experts" generated

a lot of good comments, and a strong request to continue this

type of format at future roundups. Several people said it was

the best tech session they had ever attended. Having the questions

written down gives the panel members a chance to read and understand

the questions and determine which panel member can best answer

the question. We had a California Highway Patrol Officer give

a very informative session on the "Rules of the Road",

plus she stayed around to answer any and all questions from the

audience. Gene Fisher and Al Chernoff used their laptop computer,

connected to a big screen TV, to show all the GMC info that is

available on the net. The tech sessions ended on a good note with

a successful pressurized leak test on Al Single-ton's and Al Top's

coaches. We found lots of leaks so we had a good opportunity to

demonstrate how to seal them.

We again had some great technical sessions in Ukiah. We learned

everything you need to know about toilets, holding tanks, and

waste technology from MicroPhor Company. Duane gave his usual

good session on "What Every New GMC Owner Should Know",

plus he had a lot of follow up discussion. The session on "Bring

Your Written Question To The Panel Of Experts" generated

a lot of good comments, and a strong request to continue this

type of format at future roundups. Several people said it was

the best tech session they had ever attended. Having the questions

written down gives the panel members a chance to read and understand

the questions and determine which panel member can best answer

the question. We had a California Highway Patrol Officer give

a very informative session on the "Rules of the Road",

plus she stayed around to answer any and all questions from the

audience. Gene Fisher and Al Chernoff used their laptop computer,

connected to a big screen TV, to show all the GMC info that is

available on the net. The tech sessions ended on a good note with

a successful pressurized leak test on Al Single-ton's and Al Top's

coaches. We found lots of leaks so we had a good opportunity to

demonstrate how to seal them.

Clarification on Propane Cylinders

In the June 2000 issue of Highways Magazine, on page 70, there

is a question-and-answer section where the person answering the

question on propane cylinders made a statement about propane cylinders

having to be replaced by the year 2002. The question has to do

only with portable type cylinders used in RV trailers. These are

considered portable tanks as they can be removed for filling.

The need for replacement does not apply to propane tanks used

in motorhomes (our GMCs included). Motorhome tanks are not removable

and are designed to ASME Standards different from those used on

RV trailers

Entrance Door Adjustment

When I walk around and talk to people at the various club rallies,

I notice that a lot of entrance doors do not close properly. The

maintenance manual does not show anything about how to adjust

door closure. On the two 76 GMCs we purchased, the entrance door

would not close far enough to engage the primary latch position,

even with the striker plate adjusted all the way to the outboard

position. You can check the proper door latching by closing the

door slowly and observing both the secondary and primary latch

functioning. You should hear two clicks. If it is not closing

on the primary latch, loosen the four bolts attaching the door

striker and move the striker plate outward. The striker plate

has about 1/4-inch adjustment capability as it came from the factory.

If the door still does not close on the primary latch, you need

to make a small modification. Remove the four bolts that attach

the striker plate. You will see the bolts go through oversize

holes in the body doorframe. There is a floating nut plate behind

the two outboard bolts. The two inboard bolts use standard washers

and nuts that are accessible from inside the coach next to the

inside wall. Using a rotary file or metal router bit, enlarge

the holes in the frame about ¼-inch in the outboard direction,

being careful not to damage the threads in the nut plate. Now

you should be able to reinstall the striker plate and move it

out far enough for the door to close on the primary latch. You

may need to remove some material from the outboard side of the

striker plate if it is interfering with the door closure. Some

of the striker studs (what the door latches on) are loose or are

dislocated so badly that the stud has to be drilled out, repositioned

and welded to the striker plate.

I have also noticed a lot of the entrance doors do not fully close

at the top and/or bottom. When you see doors that are bent out

at the top and bottom, it is usually on a coach that has had the

door "stop strap" removed. And you can usually see a

fairly deep dent in the body rub rail where strong winds have

caught the door and slammed it against the rub rail. It may not

seem possible, but many people have observed their door being

bent in this way. GM put the strap on the door for a very good

reason.

Engine Oil Leak

Bill Harvey had a recent experience with an oil leak coming from

the front of his engine. He was not surprised as he has over 150,000

miles on his engine. Even though oil is relatively inexpensive,

he decided he had better see if he could find the source of the

leak. He had a good clue as the oil was dripping off the cross

member under the front of his engine. Further inspection showed

it was leaking from the engine front cover seal around the harmonic

balancer shaft. Reviewing his trusty maintenance manual showed

it was not a big job to replace the seal. His biggest task was

finding how to loosen the power steering pump to remove the v-belts

and moving the fan shroud forward to gain access to the harmonic

balancer. The maintenance manual showed the type of puller needed

to remove the harmonic balancer. After it was removed, the seal

was easy to pop out with a screwdriver, and it was very easy to

install a new seal.

Fig. 1. Harmonic Balancer

Careful inspection of the shaft area on the harmonic balancer

showed a very faint groove where the seal had been rubbing. Bill

was aware there was a kit available to repair the shaft, and a

trip to his trusty NAPA store took care of the problem. Their

P/N 999199 fits all the Toronado engines of our era. Their kit

contained good directions, along with a tool to drive the sleeve

on the shaft. The discolored area near the top of the shaft on

the harmonic balancer, shown in Fig.1, is where the seal had been

rubbing. Also shown lying on the harmonic balancer is the sleeve

that Bill used to repair the worn shaft.

Note the timing line on the harmonic balancer has been highlighted

with white paint. If you haven't done this previously, now is

a good time to do it. Also, if you have more than 90,000 miles

on your timing chain and /or your water pump, now is a good time

to put on new ones. The task is more than half-done with the harmonic

balancer already off.

Safety Gauges

Modern day cars have several computers that control and monitor

various functions as we drive down the road. If something malfunctions,

the computer gives a warning such as "check engine"

or other indicators to let us know something is wrong.

We don't have this type of monitoring system on our classic GMCs,

but we can add gauges that will do a similar function. There is

a small company called "Westberg Mfg. Inc." located

in Sonoma, CA that makes numerous "Westach" gauges for

automotive, aircraft, and marine applications. They make a series

of gauges that have a built-in super bright LED warning light

that can easily be adjusted to come on at whatever temperature

or pressure you want to be notified. There is also a pin on the

back of the gauges that can be used to operate an auxiliary light

or buzzer.

I have four of these gauges on our GMC: one for engine oil pressure,

one for engine oil temperature, one for engine coolant, and one

for transmission oil temperature. I have all these gauges connected

to a common bright red light located in the dash in front of the

driver and also to a common loud buzzer. I have the "set

point" on the three temperature gauges just a few degrees

above their respective normal maximum operating temperatures.

The oil pressure "set point" is on the low side, a few

psi below the normal minimum operating pressure.

I don't have to monitor my gauges as I drive, because I know they

are monitoring the four critical functions. If the buzzer goes

off, all I have to do is glance at the gauges to see which one

has its LED turned on and make a judgment as to what I need to

do to possibly save my engine or transmission.

Wesberg is a small company, and they are very amenable to work

with. They will make about any type of gauge you want including

dual function gauges. They even installed the temperature-sending

unit inside the drain plug for my engine. I have one of their

dual function gauges to monitor air bag pressure and another one

to monitor engine vacuum and RPM. If you are interested in automatic

monitoring of critical functions on your vehicles, you can call

them at 1-800-400 7024, and they will send you their catalog.

Air Fuel Ratio Gauge

Both Chuck Garton and I have a Westac analog air fuel (A/F) gauge

to monitor the operation of the fuel induction system. An O2 (oxygen)

sensor located in the exhaust system drives this gauge. It reads

from 17 (lean) on the left to 12 (rich) on the right with the

ideal ratio of 14.7 marked near the center.

The A/F gauge operates the same on both of our GMCs. Under normal

driving with a light load and high engine vacuum, the gauge needle

stays all the way to the left, indicating a lean fuel mixture.

When the engine load is increased sufficiently to cause the vacuum

to drop below 7 inches, the gauge needle slowly swings all the

way to the right due to the power valve in the carburetor enriching

the fuel/air ratio. The needle stays all the way to the right

as long as engine vacuum stays below 7 inches. When the engine

load is decreased sufficiently to cause the vacuum to increase

above 7 inches, the carburetor power valves closes, and the A/F

gauge needle swings all the way left, again indicating a lean

fuel mixture.

These A/F gauges have not been calibrated, so the mixture reading

is not precise. However, when used in conjunction with a good

engine vacuum gauge, they can be very beneficial in showing proper

carburetor operation.

Chuck Garton had a recent experience where his A/F gauge indicated

there was something strange going on in his engine. When his vacuum

dropped below 7 inches, the gauge properly indicated fuel enrichment

by moving all the way to full rich. But, after a short time at

low vacuum, the needle slowly moved left to full lean indicating

the carburetor was not working properly (not supplying enough

gas). He first checked his carburetor and found it to be okay.

He next replaced his O2 sensor that drives the A/F gauge. However,

the symptoms stayed the same. He recalled reading a recent article

by Wes Caughlin discussing problems with cracked intake manifolds

causing lean fuel mixtures. Inspecting his manifold revealed extensive

cracking in the area under the carburetor. He replaced his intake

manifold and his A/F gauge showed everything was back to normal.

When he applied a heavy load to his engine, the hot exhaust gasses

heated the area under the carburetor causing the manifold crack

to get larger. This allowed the exhaust to dilute the air/fuel

mixture, which caused the lean fuel condition that was properly

indicated by his trusty A/F gauge. If this condition had gone

on undetected for a long time, it could have resulted in burnt

exhaust valves. Thus, his A/F gauge may have saved him some big

bucks ($).

Parking Brake Adjustment

You hear a lot of people complaining about how poorly their parking

brake works on their GMCs. Some say: "It is absolutely no

good, so I disconnected it". I don't know how people get

along without a parking brake unless they carry along blocks and

have their passenger get out and chock the wheels whenever they

park on a steep incline. If you have to rely on the "parking

paw" to hold your coach on a steep hill, you may not be able

to get it out of park. If you try to take it out of park with

a high load on the parking paw, you may damage the transmission.

The parking brake on our GMCs works adequately if they are properly

adjusted. First, your rear brakes must be in good working condition,

and they must be properly adjusted to keep the brake shoes in

near contact with the brake drums. The automatic adjusters do

not work very well on our GMCs because of our limited usage and

braking while backing. There are two modifications discussed later

that will considerably improve the barking brake function.

The best way I have found to adjust the parking brakes is to jack

up the rear of the coach and place it on jack stands, so all four

wheels are off the ground. Release the parking brake and turn

the brake parking handle knob counterclockwise until it is all

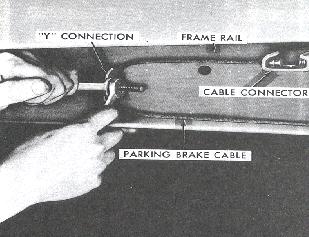

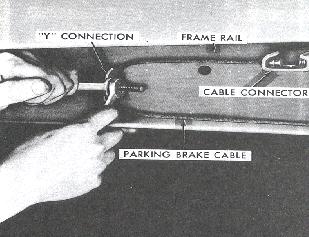

the way out. Loosen the adjustment nuts at the "Y" equalizer

on the outside of the frame rail where the single cable coming

from the front connects to the dual cables going to each set of

rear brakes, as shown in Fig.2. Make sure there is no tension

on these cables. Manually pull and release the cable going to

each rear brake and verify the cable slides freely within its

housing. If not, they need to be replaced.

Fig.2. Adjusting Parking Brakes

Adjust the rear brake shoes on

all four wheels by turning the brake adjustment screw and expanding

the brake shoes until each wheel can just be turned by hand. With

the vehicle engine running, apply the vehicle road brakes as hard

as you can. Recheck and/or readjust each rear brake shoes so they

all have about the same drag. Back off the brake adjustment screw

on each wheel (you have to release the automatic adjustment lever

with a small screwdriver) until the wheel just starts to turn

freely with only a slight drag. Reapply the vehicle road brakes,

and then recheck the rear wheels to make sure they still turn

freely. Now you are ready to adjust the parking brakes.

Tighten the adjustment nut (at the "Y" connection) a

few turns, alternating from side-to-side, until you start to feel

some drag on each wheel. If the drag is not uniform, you need

to equalize the cable pull on each wheel by sliding the cable

within the intermediate guide (at the "Y" connection)

until you have equal drag on each wheel. It is sometimes difficult

to slide the cable within the guide as the cable tends to get

bent into the shape of the guide. It is very important to do this

step so you will have equal pull on each wheel and remove all

the slack in the parking mechanism. From this point on, you should

be able to take any additional slack out of the system by adjusting

the knob on the parking brake handle. This knob should be kept

adjusted to the point you are just able to pull the parking brake

to the "locked" position. One of the shortcomings of

the GMC parking system is the limited amount of cable travel provided

by the brake handle mechanism. Thus, you have to keep the rear

brakes properly adjusted to have adequate parking brakes.

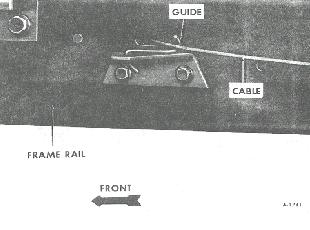

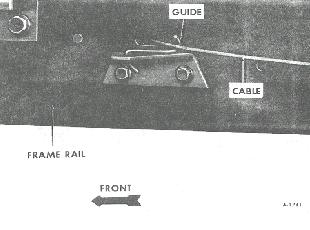

Parking Brake Modifications

The parking brake function and adjustment can be improved by making

two simple modifications. The first one is to replace the "hook"

guide where the cable goes through the frame rail (shown in Fig.3).

Fig. 3. Hook Guide for Brake Cable

Go to the Home Depot section where

they sell hardware for sliding glass doors and purchase two of

their larger ball-bearing rollers (about 1.5" in diameter)

that have a groove around the outside diameter. Loosen the brake

cables and place the roller on top of the bracket that holds the

"hook" guide. Align the roller on the bracket so the

cable will go around the roller, and through the slot in the frame

rail without dragging on the frame. Mark the location of the roller

center hole on the bracket and remove the cable. Drill a hole

in the bracket the same size as the roller center hole. Pack the

roller-bearing with grease and install a large "fender washer"

on top of the roller. Bolt the roller to the bracket using a locking

nut. Install the cable into the groove on the roller and you now

have one of the modifications complete.

The second improvement involves replacing the guide at the "Y"

connection on the outside of the vehicle frame where the parking

brake adjustment is made. While you are in Home Depot purchasing

the above discussed rollers, go to their garage door section and

purchase two of their ball-bearing pulleys used to guide the return

spring cables on overhead garage doors. They are about the same

diameter as the spacing between the two cables going to the rear

brakes. Using 1/8"x1.0" wide steel bar, make a "U"

shaped bracket about five inches long. Drill a hole in the center

of the "U" to fit the threaded area on the end of the

front cable. The "U" legs need to be far enough apart

to get a box-end wrench between the legs so the adjustment nut

can be turned. Drill matching holes near the end of the "U"

legs to match the center hole of the pulley. You will need to

put a small "dog-leg" in the legs of the "U"

as the thickness of the pulley is less then the width needed for

the adjustment wrench. Saw off about half of the threaded section

on the front cable. If the shortened threads do not provide sufficient

adjustment capability, there is another cable adjustment under

the coach that can provide additional adjustment. Remove the OEM

guides at the "Y" connection on each side of the vehicle

and replace them with the new pulleys. Place the "U"

bracket over the pulley and bolt the pulley to the bracket using

a locking nut. Insert the threaded end of the front cable through

the hole in the "U" and install the adjustment nut.

You need a nut on each side of the bracket so they can be "locked"

same as with the OEM guide.

You can now adjust the rear parking brakes using the procedure

discussed previously. However, you won't need to go through the

tedious procedure of trying to balance the pull going to each

of the rear brakes; the pulleys do that for you.

The material for the two above modifications will cost you less

than $20, and you will realize a significant improvement in your

parking brake function. Remember that the proper way to "set"

your parking brake is to first apply and hold the foot brakes,

then apply the parking brake. The parking brake will develop significant

more braking capability if the rear shoes are already expanded

tightly against the drums when the parking brake is applied.

|

This material is based on

my personal experience and the personal experience of other club

members. It is our viewpoint and does not represent authorized

data pertaining to the GMC Motorhome. It is the responsibility

of the readers to make their own judgment as to the validity

of this material in relation to any repairs and/or modifications

to their own vehicles. |

Please send your

comments and ideas for the Tech Center to:

Chuck Aulgur, Technical Vice President,

9805 Ogram Dr., La Mesa, CA 91941

Phone: (619) 465-9875

E-mail: cwasdc@juno.com |

We again had some great technical sessions in Ukiah. We learned

everything you need to know about toilets, holding tanks, and

waste technology from MicroPhor Company. Duane gave his usual

good session on "What Every New GMC Owner Should Know",

plus he had a lot of follow up discussion. The session on "Bring

Your Written Question To The Panel Of Experts" generated

a lot of good comments, and a strong request to continue this

type of format at future roundups. Several people said it was

the best tech session they had ever attended. Having the questions

written down gives the panel members a chance to read and understand

the questions and determine which panel member can best answer

the question. We had a California Highway Patrol Officer give

a very informative session on the "Rules of the Road",

plus she stayed around to answer any and all questions from the

audience. Gene Fisher and Al Chernoff used their laptop computer,

connected to a big screen TV, to show all the GMC info that is

available on the net. The tech sessions ended on a good note with

a successful pressurized leak test on Al Single-ton's and Al Top's

coaches. We found lots of leaks so we had a good opportunity to

demonstrate how to seal them.

We again had some great technical sessions in Ukiah. We learned

everything you need to know about toilets, holding tanks, and

waste technology from MicroPhor Company. Duane gave his usual

good session on "What Every New GMC Owner Should Know",

plus he had a lot of follow up discussion. The session on "Bring

Your Written Question To The Panel Of Experts" generated

a lot of good comments, and a strong request to continue this

type of format at future roundups. Several people said it was

the best tech session they had ever attended. Having the questions

written down gives the panel members a chance to read and understand

the questions and determine which panel member can best answer

the question. We had a California Highway Patrol Officer give

a very informative session on the "Rules of the Road",

plus she stayed around to answer any and all questions from the

audience. Gene Fisher and Al Chernoff used their laptop computer,

connected to a big screen TV, to show all the GMC info that is

available on the net. The tech sessions ended on a good note with

a successful pressurized leak test on Al Single-ton's and Al Top's

coaches. We found lots of leaks so we had a good opportunity to

demonstrate how to seal them.