This

tech issue is going to be a mixture of several short subjects

relating to maintenance, improvements, safety, and a few other

things. I hope some of them will be of interest to you:

This

tech issue is going to be a mixture of several short subjects

relating to maintenance, improvements, safety, and a few other

things. I hope some of them will be of interest to you:|

|

|

|

|

|

By Chuck Aulgur

This

tech issue is going to be a mixture of several short subjects

relating to maintenance, improvements, safety, and a few other

things. I hope some of them will be of interest to you:

This

tech issue is going to be a mixture of several short subjects

relating to maintenance, improvements, safety, and a few other

things. I hope some of them will be of interest to you:

The material presented in this document is based on my personal experience. It is my viewpoint and does not represent authorized data pertaining to the GMC Motorhome. It is the responsibility of the readers to establish their position associated with this subject in relation to any vehicle repair and/or modifications.

Maintenance

With the exception of people living in the southeastern and southwestern

states, your trusty old GMC has probably been semi-retired for

the winter. No matter where you live, now is a good time to take

a look at your GMC maintenance logbook or service records, and

see what needs to be done before spring travel begins. Most of

us who purchased used GMCs, and started attending the various

GMC club rallies, were soon made aware of the critical items that

need special attention to prevent serious and costly problems.

Most of us got scared out of our pants at our first rally and

got these items taken care of in due fashion, and a few sold their

coaches as soon as they returned home. A high percentage of GMC

owners are senior citizens, like myself, and we find that time

passes faster and faster as we enjoy our retirement years, and

some of us have a few "senior moments" along the way.

As I was looking through my GMC logbook recently, I found it

hard to believe how long it had been since I last attended to

some of the critical items. If it happened to me, maybe it is

a good time to remind everyone to take a look at his or her maintenance

schedule. Another thing that I have found helpful over the years

is about once a year, when there is a rainy day and I don't have

anything important to do, I skim through all the past GMCWS and

GMCMI newsletter tech sections and the Cinnabar GMCMHN quarterly.

I usually find something of interest that helps solve some current

problems or it reminds me of some-thing I need to do.

Front Wheel Bearings:

One of the most critical items on our GMCs is probably the front

wheel bearings. If your records show it has been more than 25k

miles since you serviced them, you need to take care of them soon.

If you burn out a front wheel bearing while traveling at highway

speeds, you are talking about some big bucks. I know from personal

experience that you can lose a front wheel hub, the brake disc

and pads, the knuckle, and even the drive axle. This all happened

to us the first year we owned our current GMC. The previous owner

said he had just replaced the front wheel bearings, so they were

one of the few items I didn't bother to check, how-ever, they

failed in less than 10k miles. They were the old type S-23 Bower

bearing. The newer higher load-rated bearing that has been available

from Cinnabar for several years helps this problem considerably.

However, they still should be serviced or replaced approximately

every 25k miles. With periodic re-lubing, some people have gotten

over 100k miles on these bearings, but they are usually people

that do their own work and are not concerned about labor cost.

My recommendation is to just replace the bearings as their cost

(less than $100) is minor compared to the cost of a bearing failure.

If you are having your bearings replaced at a repair facility,

and you want the extra security of the 20 percent more load-carrying

capacity, make sure you specify GM P/N 12351677 as they may install

the less expensive generic set S-23 bearings.

Rubber Products:

Another critical item that should be looked at is how long it

has been since the rubber products were renewed. These include

the fuel line hoses, the radiator hoses, the oil cooling line

hoses, the power steering hoses, the engine v-belts, and the vehicle

tires. The industry standard recom-mends that these rubber products

be replaced at least every seven years. It may be required much

sooner for the fuel line hoses, as the fuel we are now burning

is said to be extremely hard on the rubber hoses. Also, if you

have an auxiliary transmission oil cooler that was installed using

rubber hoses, make sure the hose is designed for that usage.

I have seen regular fuel line hoses used for this application.

A hose that is not designed for this high tem-perature and pressure

application can get soft and fail in a very short time. When

you replace your fan belts make sure you get 12-mm-wide belts.

A lot of the belts being sold for our GMCs are only 11-mm and

ride to far down in the v-pulley. Good-year is one company that

still makes the 12-mm belts.

A lot of us can speak from personal experience as to how much

it cost to repair the damage caused by tread coming off a tire

when traveling at highway speeds. In my case, I had four Michelin

tires with non-steel sidewall cords that were less than five years

old, fail on one trip - the coach damage was over $2000. Take

a look at the date code on your tires and you may be surprised

at how old they are. The date code is shown as three numbers

- the last number indicates the last digit of the year and first

two numbers indicate the week they were manufac-tured in that

year (246 indicates the 24th week of 1996 - assuming they are

less than 10 years old). If the age is approaching seven years,

it's time to see the tire man. If the tires are not all-steel

cords, the recommended life is about four years or less.

Probably the most critical rubber product on our GMCs is the engine oil cooling line hoses. If one of them fails while driving, it can easily destroy an engine in a very short time. There are a lot of GMC owners that can attest to this. When replacing these hoses, use the OEM material as higher pressure hoses tends to be much stiffer and can cause excessive loading on the structurally weak radiator fittings causing them to fail.

I can hear a lot of you thinking, why is he wasting our time telling us all this stuff we already know. My only point is to remind you to look at your records and see what critical items need replacing before it provides info for another horror story in the GMC Motorhome Marketplace.

Carburetor: The carburetor and intake manifold are items causing a lot of problems on high-mileage engines. If you are experiencing hard starting with a cold engine, or long delays in coming off of fast idle, it is probably due to improper automatic choking. Remove the side cover from the automatic choke and take a look inside. If you see a lot of carbon buildup, you most likely have a hole burned in the heat tube assembly (item 8 in on page 8-9 of 78Z parts book) similar to what is shown in Fig. 1.

This heat tube is exposed to exhaust gases and the tube burns through after a lot of miles. When this happens, exhaust gases are forced up into the choke area which soon causes it to malfunction. The carburetor choke assembly will need to be cleaned and the heat tube assembly replaced. When you replace the tube assembly, you may want to modify it by adding a piece of stainless steel similar to what is shown in Fig. 2. The added stainless steel plate should be as large as you can get through the hole in the manifold and is welded to the heat- tube-mounting flange.

Fig. 1. Heat Tube Assembly

Fig. 2. Heat Tube Assembly With Stainless Steel Plate

Almost everyone who removes their carburetor and inspects the intake manifold find them cracked in the area between the large secondary carburetor ports. The crack does not cause a problem until it extends down into the bottom section of the mani-fold. When this happens, exhaust gasses can leak into the intake manifold. The reason for installing the modified tube assembly with the stainless steel plate is to block most of the exhaust gasses going through the passageway under the carburetor. The manifold is exposed to too much heat in the area under the carburetor which causes it to crack over time. By blocking most of the exhaust gasses it may prolong the useful life of your manifold. People who are familiar with this problem are blocking off most of the flow through the exhaust passageway going under the carburetor when they have their intake manifold repaired or replaced. I have heard there is a com-pany that makes intake manifold gaskets for our engines used in boat racing applications that has the exhaust port going under the carburetor blocked off. However, I don't know the company name. If any of you know about this gasket, please let me know, as it would be helpful to our club members. If you happen to run across a used intake manifold that is not cracked, I recommend you obtain it for a spare - they are getting very hard to find.

Improvements

Radiator Guard:

When I attend GMC rallies, I normally walk around and look at

all the other coaches to see what improvements or modifications

other people have made. I am always amazed to see how many coaches

are still being driven without a guard on the lower part of the

radiator. One of the things that attract us to the GMC is their

lowness to the ground. Unfortunately, this can cause a serious

problem as the lower 1/3 of the radiator is exposed to flying

objects kicked up from the road. A small rock can knock a hole

in the radiator and cause the coolant to leak out while you are

trucking down the road listening to the stereo, or watching the

country-side pass by instead of watching the temperature gauge.

It doesn't take very long to overheat the engine to the point

a head gasket is blown and/or the heads are warped or cracked

beyond repairs. It is getting extremely hard to find serviceable

used engine parts for these classic coaches, so it be-hooves us

to take good care of what we have. This can all be avoided by

placing a protective screen in front of the radiator. A 36-inch

wide by 18-inch long piece of one inch expanded metal, covered

in front with ¼-inch square mesh screen and attached between

the lower radiator support frame and the forward vehicle cross

member, can prevent a serious problem. Bend the screen up in

front of the frame cross member so it covers the large holes.

Bend the lower end horizontal where it goes under the radiator

support frame. Attach it using a few fender washers and ¼-inch

metal screws. Drill the screw holes in the radiator support frame

very close to the front edge so as not to damage the radiator.

The expanded metal can be purchased at metal supply stores or

at metal salvage yards. You can also purchase it at Home Depot,

but you may have to make it out of two 18-inch square pieces as

they only stock small pieces. It only cost a few dollars and

a little time, but it may save you hundreds of dollars. The ¼

square screen (sometimes called chicken wire) is not adequate

by itself. I had a piece of truck tire tread knock a hole through

a ¼ -inch square screen wire and severely damage a new

radiator core. Do not use window screen wire for this application

as it can severely block airflow to the radiator.

Rattles:

If you have noticed that your GMC has more rattles than in its

younger days, it is most likely due to degradation of the insulating

material between the coach body and chassis frame. The 73 through

mid-76 coaches came with a continuous strip of rubber between

the chassis frame and the coach body as shown on page 23-76 of

78Z parts book. Mid-76 and later coaches came with twenty separate

pieces of rubber located at the points where the body floor cross-members

pass over the top of the chassis frame side rails. When I examined

our coach some time back, I found six of the twenty insulators

were missing, and another four were only partially in place.

After I installed all new rubber insulators, I found it hard to

believe how much improvement it made - I thought we had a new

GMC. The old insulators that I took out were as hard as a rock

making a rigid connection between body and frame instead of a

soft one, so it's no wonder the dishes were rattling. It is not

an easy job to replace the insulators, but it is well worth the

effort. What I found that worked best was to jack up one side

of the coach to the point both the front and rear wheels were

on the verge of leaving the ground, then place jack stands under

the frame. There are two hold-down brackets on each side of the

coach located on the outside of the frame rails, that have to

be unbolted to allow the body to be raised sufficiently to unload

the insulators. Each bracket has two carriage bolts that go down

through the plywood floor. You will need to apply liquid-wrench

or a similar material to the bolt nuts, starting several days

before you try to remove the nuts, as they are rusty, and it doesn't

take much torque to turn them in the wooden floor. The bolt heads

are most likely inaccessible from inside the coach. Once these

hold-down brackets have been removed, start at the front end of

the frame and place bottle jacks under the first two floor cross-members.

Jack the body up until there is approximately ½ -inch

clear-ance between the front cross-member and the frame. Remove

the old insulator and thoroughly clean the frame and cross-member

surfaces with a solvent. Coat both surfaces and the new insulator

with 3-M weather strip cement and install the new insulator in

the first position. Remove the first jack and place it under

the third cross-member and again jack up the body and replace

the second insulator. Repeat until all the new insulators have

been installed. Using two jacks makes the job much easier because

you don't have to do as much jacking once the body has been raised

to the point where is about to be lifted off the frame. When

one side is completed, repeat the same procedure on the other

side, and you will have a much quieter-riding coach. You can

purchase new insulators (P/N 2005279) or make them yourself from

5/16-inch thick sheet rubber cut into 3x6 inch rectangles. You

can purchase sheet rubber in larger cities at commercial rubber

supply houses in hard, medium or soft density - I used medium

density. It would be very difficult to replace the continuous

insulator on the early coaches without removing the body from

the frame. However, you can use the same above procedure by removing

the old rubber under the body cross-members and inserting a new

piece in its place. The remaining sections of rubber lying between

the cross-members are not supporting any weight, so there is no

reason for it to be changed.

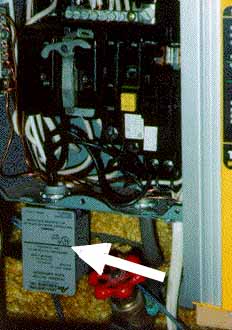

Safety

A lot of us GMC owners have added new gadgets and appliances with

sensitive electronic controls such as computers, microwave ovens,

television, radios and numerous safety monitoring devices. If

these items are subjected to power surges, either from the Onan

generator operation or shore power, they can be severely damaged.

Adding a perma-nently mounted surge suppressor to the main circuit

box can protect all of the items in your motor home. These units

can be purchased at electrical supply stores in the range of $25

to $60, depending on what brand they carry. They are designed

to be installed in a home electrical circuit breaker box with

two 110-volt circuits. However, they will also work in our motorhomes.

They are small units around 4 cubic inches in size, with a 1/2-inch

male fitting designed to fit through a 1/2-inch knockout in the

breaker box. One ground wire is connected to the circuit breaker

box ground terminal. The other two "hot" wires connect

to two different circuit breaker output terminals. Coaches with

GM interiors have 50-amp shore power with two 110-volt lines coming

into the circuit breaker box, each going through a separate 40-amp

main circuit breaker. The surge suppressor wires are connected

to the output terminal of one circuit breaker downstream of each

main circuit breaker. The Royale and Birchaven coaches have 30-amp

shore power with only one 110-volt shoreline coming into the main

circuit box, and one 110-volt line coming from the Onan generator,

each going through a separate 40-amp main circuit breaker. The

two "hot" surge suppressor wires can be con-nected to

the output terminal of any two of the line circuit breakers downstream

of the main breakers, or you can just cap one of the wires. The

arrows in Fig. 3 and Fig. 4 below point to two different brands

of surge suppressors mounted on two different circuit breaker

boxes; Fig. 3 is a GM interior and Fig. 4 is our Royale interior.

Fig. 3. Surge Suppressor on GM Interior Breaker Box

Fig. 4. Surge Suppressor on Royale Breaker Box

This may all sound a bit complicated, but it really is a very simple installation. The units come with a good wiring diagram and it should take less than one hour to install one, and it could save destroying an expensive electronic unit somewhere down the line.

Attention

I have received very little information or questions in the last

three months as to what you members want to see covered in this

tech section. One could assume that you have no items that you

want discussed or answered, so maybe there is no need for this

tech section. It takes member participation to make this club

effective. Let's get that snail-mail,

e-mail or telephone in operation!

|

|

|

|

|

Chuck Aulgur, Technical Vice President, 9805 Ogram Dr., La Mesa, CA 91941 Phone: (619) 465-9875 E-mail: cwasdc@juno.com |

|

|

|